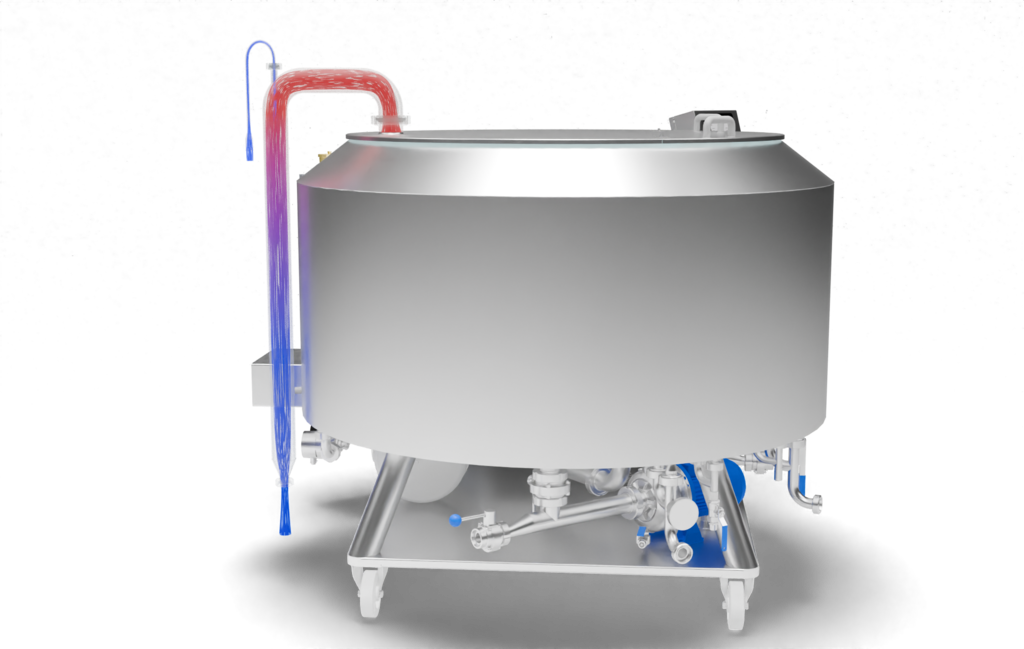

A vapour condenser is an essential element in breweries that plays an important role in beer production. During the boiling process in the wort kettle, water vapour containing flavor compounds and unwanted volatile compounds is produced. The vapour condenser is used to capture, remove, and condense this vapour. This helps to minimize emissions into the environment and the premises.