Heating system

In modern breweries, the choice of heating system for the mash and wort kettle plays a crucial role in the efficiency and quality of the brewing process.

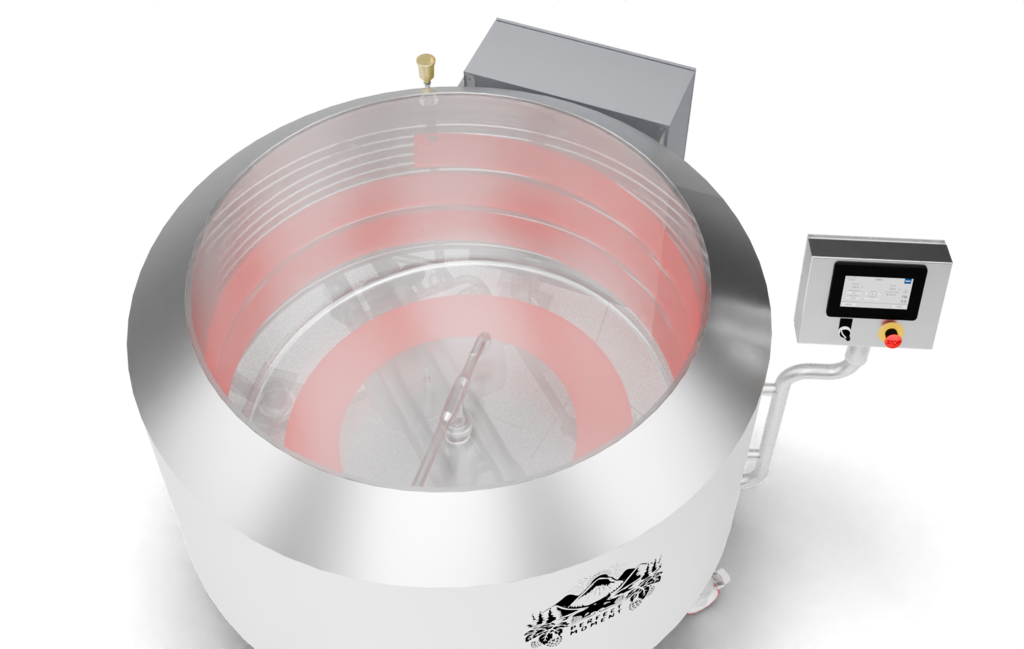

The indirect heating method is particularly popular, which is done through both the vessel walls and the vessel bottoms. This method offers numerous advantages: it ensures even heat distribution, ensuring efficient energy utilization, and also allows for easy cleaning of the vessels.